Energy savings in the enterprise - key tips:

- Save electricity

- Reduction of heat and steam loss

- Steam line loss reduction

Energy Saving in Enterprise - Energy Saving Methods

- Selection of optimal price categories and review of power supply contract terms

- Optimization of electric motors

- VFD installation

- Optimizing the compressed air system

Select the optimal price category for the power supply

In total, there are 6 price categories of electricity supply, for which enterprises can purchase electricity from guaranteed suppliers.

All small enterprises with an installed capacity of less than 670 kW, at the time of signing the contract for automatic power supply, are included in the first price category.

All enterprises with an installed capacity of more than 670 kW automatically belong to the third price category.

The first and third price categories are not always the most optimal and cheapest power supply categories.

In some cases, switching to a different price category can reduce electricity costs by 5% -30%.

The topic of price categories is quite broad, in our review of price categories, we tell in detail how to calculate and choose the price category of electricity supply correctly.

In addition to the price categories, we also recommend looking at other aspects of the power supply contract:

- voltage level,

- power,

- electricity transmission tariffs.

In our survey, you can learn about this method and other methods to reduce energy costs.

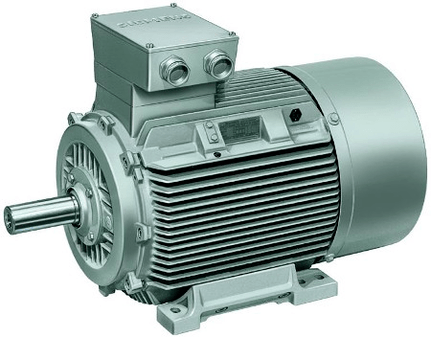

Energy Saving in Enterprise - Electric Motors

Need to take into account all equipment in which electric motors are used:

- pam,

- compressor,

- fans,

- machine tools,

- production line.

Electric motor control plan

The motor control plan should be an integral part of the plant’s energy saving program.

Such a plan would help implement a long -term energy saving system for all electric motors in the enterprise.

A motor control plan will ensure that failures and damage do not occur, and if they do occur, are resolved quickly and efficiently.

Steps to create a motor control plan:

- Conduct an inventory of all engines at the facility.

- Make a list of the engine with its main parameters, technical condition, service life.

- Develop general guidelines for making repairs.

- Develop guidelines for preventive maintenance, lubrication and inspection.

- Make a safety stock of frequently used spare parts.

- Create purchase specifications for the new machine.

Rotate the electric motor

In general, recycling an old electric motor is much cheaper than buying a new one.

The electric motor should be replaced if the cost of turning it exceeds 60% of the new cost.

Then it will all depend on how the rewind is run.

If the work is done at the highest level, then the motor will lose its efficiency of only 1% -2% percent.

If the rewinding is done badly, then the loss on the electric motor will increase by 5% -10%.

Replacing an old electric motor with a new energy efficient one makes sense if the motor operates more than 2000 hours a year.

The payback period for new energy efficient engines is not more than 1. 5 - 2 years.

Energy saving in the enterprise by increasing the load factor

The load factor is the ratio of operating power to real power.

That is how energy is used efficiently.

The higher the load factor, the more efficiently electrical energy is used.

The electric motor operates optimally at a load of 75% and above.

Therefore, installing a motor in excess of the required force (for safety reasons) is not only more expensive, but also inefficient in terms of energy consumption.

The load factor can be increased as follows:

- turn off an unloaded engine,

- engine replacement, less than 45%loaded, for less powerful models,

- load redistribution between existing electric motors.

Variable frequency drive (VFD)

The installation of variable frequency drives only makes sense for dynamic systems.

In static systems, which are involved, for example, only to lift loads, the installation of variable frequency drives will not help, and can often be harmful.

The VFD balances the load and speed of the motor, thus ensuring that electrical power is used optimally.

VFD can reduce motor energy consumption by a minimum of 5% and a maximum of 60%.

The repayment period for VFD is usually 1-3 years.

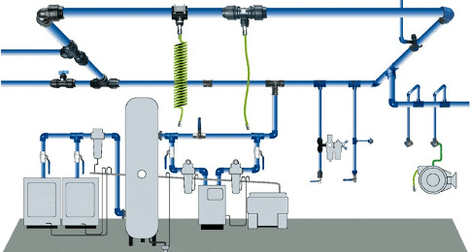

Optimization of compressed air systems

Compressed air is used in a variety of industries.

In some companies, compressed air is the main consumer of electricity.

Compressed air is used in pneumatic tools and equipment, on conveyors, automatic ducts.

The use of compressed air is popular because it is a convenient and safe source of energy.

But many people forget that compressed air is one inefficient source of energy - only 5% of the electricity spent on the production of compressed air turns into useful work, the remaining 95% goes out into the pipes.

Energy savings in the enterprise - compressed air:

- Do not use compressed air to clean the premises.

- Reducing the air temperature in the compressor inlet by 3% reduces power consumption by 1%.

- For such technical processes, if possible, reduce the compressed air pressure to a minimum. Lowering the pressure by 10% reduces power consumption by 5%.

- Perform periodic inspections, repairs of compressor equipment and compressed air delivery ducts. One, even the smallest compressed air leakage, can reduce the efficiency of equipment sometimes.

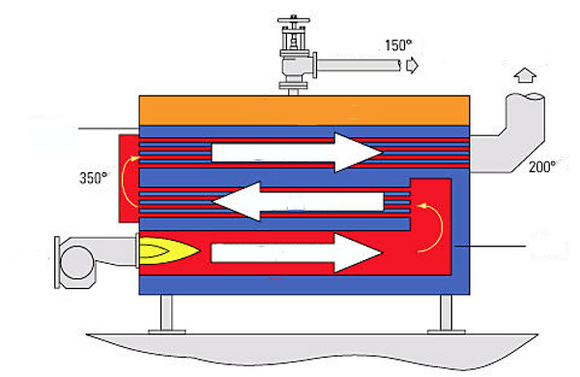

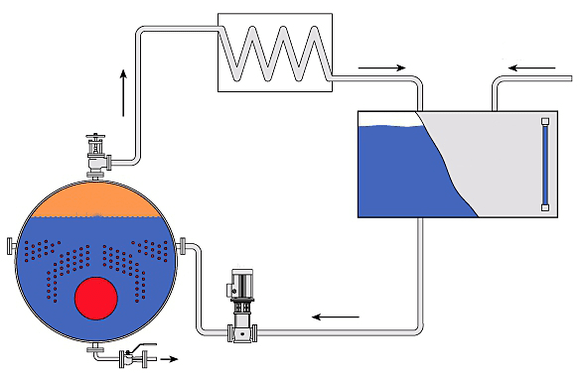

Energy savings in the enterprise - we reduce heat and steam loss

Steam is often used in industry, especially in the textile, food and processing industries.

Improving the efficiency of steam boilers and reusing the heat generated can reduce energy consumption in this plant significantly.

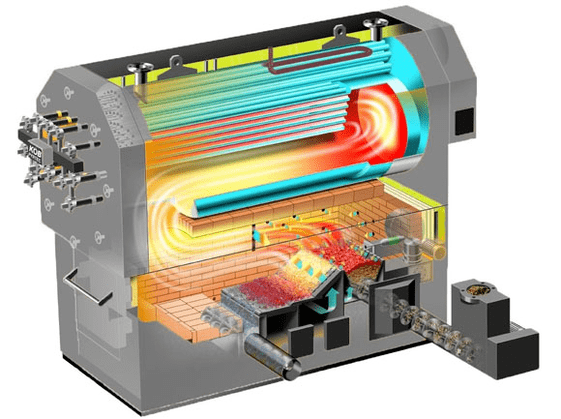

Steam production

The boiler works most efficiently at full power.

Since the demand for the amount of steam can change over time, often the boiler operates under its optimal load.

The capacity of installed boilers can be much higher than the needs of the enterprise, due to decreased demand for the product, or unrealized plans to expand production.

Also, boiler capacity may not be required due to an increase in the production process or the introduction of energy -saving measures.

In such cases, the boiler works either not at full capacity, or in a short on-off cycle mode.

Both of these situations cause significant energy loss.

There is no easy and cheap solution to this problem.

The easiest option isinstall a "small" boiler that will work at full capacitywith average or low workload in the enterprise.

Despite the fact that this is not a cheap solution, the repayment period for such investments can be less than two years.

And, in general, it is more effective to have several small interchangeable boilers, especially in enterprises that experience changing demand or significant seasonal fluctuations in heat and steam consumption.

Automatic regulation system

If the enterprise has several boilers, then it makes sense to install themautomatic system for regulating boiler load. . .

Automation responds to the steam requirements in the enterprise, redistributing the load between boilers, turning on or off the boiler, thus significantly improving the overall efficiency of the system.

Fence valve

In enterprises where the boiler is closed periodically due to a decrease in steam demand, heat loss through the chimney is quite high.

It is possible to block the loss of hot air through the chimneyby installing a gate valvewhich closes the pipe when the boiler is turned off.

Prevention and maintenance

If left unattended, the burner and condensate return system can quickly deteriorate or fail.

This can reduce the efficiency of the boiler by 20% -30%.

A moderate maintenance program - ensuring all boiler components operate at maximum levels - will significantly improve operational efficiency.

In practice, periodic maintenance reduces boiler energy consumption by 10%.

Insulation - heat loss from a properly insulated boiler surface must be below 1%.

Soot and crust removal

Need to constantly monitor and eliminate the formation of soot on the boiler tubes, scale inside the boiler.

A 0. 8 millimeter thick layer of soot reduces heat transfer by 9. 5%, while a 4. 5 millimeter thick layer reduces heat transfer by 69%!

Scale is formed when calcium, magnesia, and silicon are stored on a boiler heat exchanger.

A 1 millimeter thick scale increases energy consumption by 2%.

Soot and crust can be removed mechanically or with acid.

Soot formation and scale can be determined by increasing the temperature of the exhaust gas or by visual inspection when the boiler is not operating.

Soot and scale formation must be monitored especially carefully if the boiler uses solid fuels (coal, peat, firewood).

Gas boilers are less prone to soot problems.

Blowdown boiler optimization

Boiler blowdown is the removal of boiler water to clean the water inside the boiler from impurities and salt.

The purpose of a blowdown boiler is to prevent or reduce scale formation.

Inadequate boiler matching can cause water to enter steam, or the formation of deposits in the boiler.

Excessive exploding means loss of heat, water and chemicals.

The optimal blowdown level depends on the type of boiler, the operating pressure in the boiler, the preparation and the quality of the water used.

The first thing to pay attention to is the provision of water. If the water is treated well (low salt content), the explosion rate can be 4%.

If there are foreign substances and salts in the water, then the explosion rate will be 8% -10%.

Automatic extinguishing systems can also significantly reduce energy consumption.

The repayment period for such a system is usually 1-3 years.

Reduction of smoke emissions

Excessive smoke is often caused by the penetration of air into boilers and chimneys through leaks and openings.

This reduces heat transfer and increases the load on the compressor system.

Leaks and holes can be removed easily, just need to perform a visual inspection of the boiler and chimney on a regular basis.

Air regulation

The more air is used to burn fuel, the more heat is thrown into the wind.

An amount of air slightly in excess of the ideal stoichiometric fuel / air ratio is required for safety reasons, to reduce NOx emissions, and depending on the type of fuel.

Boilers in poor technical condition can use up to 140%additional air, resulting in excessive debris emissions.

Efficient gas burners require 2% to 3% additional oxygen, or 10% to 15% additional air, to burn fuel without producing carbon monoxide.

The general rule is that the efficiency of the boiler increases by 1% for every 15% additional air reduction.

Therefore, it is necessary to constantly check the fuel / air ratio.

The event did not require anything, but made a very good impression.

Smoke emission monitoring

The amount of oxygen in the exhaust gas is the amount of additional air (added to increase safety and reduce emissions) and the air that seeps into the boiler through holes and leaks.

The presence of leaks and holes can be easily detected if a system of monitoring the incoming air and the amount of oxygen in the exhaust gas is formed.

By using data on the amount of carbon monoxide and oxygen, it is possible to optimize the fuel / air ratio in the boiler.

The installation of a monitoring and analysis system for smoke emissions will usually pay for itself in less than a year.

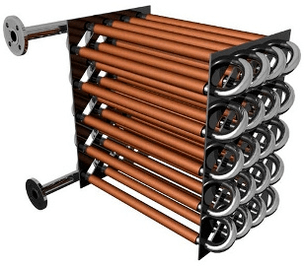

Energy Saving in the Enterprise - Installing an Economizer

The heat from the flue gas can be used to heat the water entering the boiler.

The heated water enters the boiler and requires less heat to be converted into steam, thus saving fuel.

Boiler efficiency increases by 1% for every 22 ° C drop in flue gas temperature.

Economizer can reduce fuel consumption by 5% - 10% and will bear fruit in less than 2 years.

Heat exchanger to remove heat from water and steam from blowdown boilers

The heat exchanger will help recycle about 80% of the water heat and steam from boiler boiling.

This heat can be used to heat a building or heat the water that feeds the boiler.

Any boiler with a continuous flow rate of 5% or more is an excellent candidate for a heat exchanger.

If the blowdown system is not operating in fixed mode, then it makes sense to think of switching it to fixed mode while installing the heat exchanger simultaneously.

The average payback period for heat exchangers will not exceed 1. 5 - 2 years.

Installing a condenser condenser

Hot condensate can be returned to the boiler, thus saving energy and reducing the need for treated water.

The condensation economizer can increase the efficiency of the system by an additional 10%.

The installation of such economic devices should be carried out under the close supervision of specialists who will take into account all the nuances of such a system, its effect on the boiler and the chemical composition of the water.

Using a system that returns condensate to the boiler will usually pay for itself in 1-1, 5 years.

A system that directs condensate to a hot water supply pays for itself in less than a year.

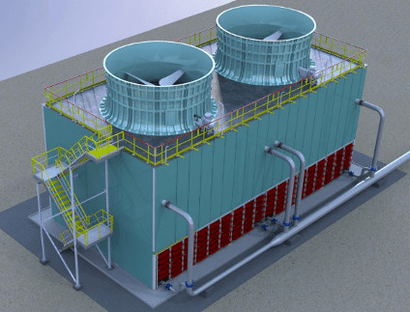

Cooling tower (cooling tower)

A cooling tower is a heat exchanger where water is cooled by a stream of air.

And in terms of energy efficiency, a cooling tower is a device that dissipates heat into the wind.

Potential energy savings in cooling towers:

- In some companies it makes sense to leave the cooling tower altogether. There are many cases when heating is used to heat a room and at the same time a cooling tower is used to dissipate heat. Installing a heat pump will solve the heating problem and at least partially reduce the need to use a cooling tower.

- Installing a circuit breaker for a cooling tower fan can reduce energy consumption by 40%.

- Replacing an aluminum or iron fan with a new fan (fiberglass and molded plastic) can reduce energy consumption by up to 30%.

Steam line loss reduction

Disconnecting Unclaimed Steam Lines

Steam requirements and uses are constantly changing.

This can lead to the fact that the entire steam distribution system is not used at full capacity, but only 20% -50%, which inevitably causes heat loss.

It is clear that optimizing or reconfiguring the entire steam distribution system to meet the new requirements would be very expensive and, possibly, feasible.

However, identifying and turning off steam ducts that are difficult to use can be a very effective energy -saving measure.

Energy saving in the enterprise - Thermal insulation of pipes

Insulating steam pipes can reduce energy loss by up to 90%.

This is one of the fastest energy -saving returns in a steam distribution system.

The average return period for pipeline insulation through which steam or hot water is delivered is around 1 year.

Condensate pipes for 1. 5-2 years.

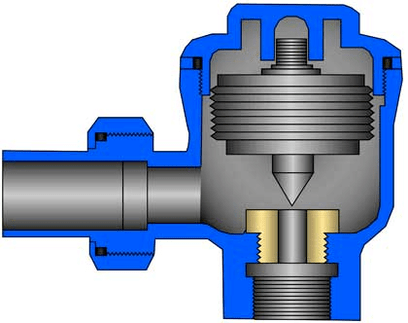

Steam trap monitoring

A simple monitoring program for the technical condition of the steam trap can significantly reduce heat loss.

For example, if maintenance is not performed for 3 to 5 years, then, as a rule, about a third of steam traps do not work properly, allowing steam to seep into the condensate drainage system.

From practice, in companies that have a steam trap monitoring program, no more than 5% of steam traps are in the wrong condition.

The average payback period for the replacement or maintenance of a steam trap is less than six months.

A steam trap monitoring program will typically reduce steam loss by 10%.

Thermostatic vapor traps

The use of modern thermostatic vapor traps can reduce energy consumption and at the same time increase the overall reliability of the system.

The main advantage of a thermostatic steam trap is that it

- open when the temperature approaches the saturated vapor level (+/- 2 C °),

- emit non -condensing gas after each opening and

- is in the open state at the beginning of system operation, which ensures fast heating.

Also, these steam traps are very reliable and can be used in a wide range of pressures.

Disconnect the steam trap

You can reduce energy consumption by turning off the steam trap on steam ducts that overheat when not in use.

Elimination of vapor leaks

A small hole steam leak repair program can pay off in less than 3 to 4 months.

We must not forget that small leaks go unnoticed for years, constantly damaging the system.

Reuse of condensate and steam

When the steam trap removes condensate from the steam system, a drop in pressure produces steam from that condensate.

This steam, along with condensate, can be used in heat exchangers to heat water or air.

Most importantly, the use of this steam and condensate is close to the point of release, as it is very expensive to make a separate piping system to transport it to the place of use.